The

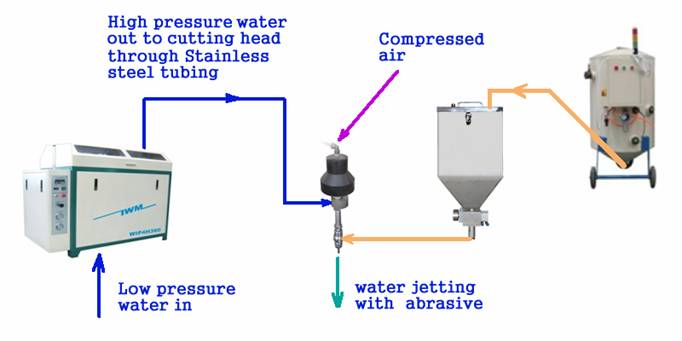

high pressure pump: Full abrasive waterjet cutting system consists of high

pressure pump, cutting table with hopper, and CNC controller.

Pump

type

|

dual plunger reciprocal intensifier

|

Maximum pressure

|

400Mpa (60kpsi)

|

Pump cooling method

|

forced

water flow, electrical chiller is optional.

|

Maximum

water flow rate

|

3.5L/minute (0.8Gal/min)

|

Water Filter

|

2-stage water

filtration included.

|

Minimum supply water pressure

to pump

|

70psi (5kg/cm2)

|

Approximate size

|

60" x 36"x 55"(1600 x900 x1400mm), weight 1100kg

|

Power source

|

3 phase,

380VAC, 50Hz (or 220V 60Hz),220VAC or 60Hz (380VAC, 50Hz)

|

Pump cooling method

|

water. Oil chiller is optional

|

Motor starting current requirement

|

160Amp

|

Protective automatic shut off under the following circumstances

|

Over pressure limit |

Over temperature limit

|

Cutting head |

|

Pneumatically

operated on/off valve, self-aligned cutting head. Maximum Abrasive flow

rate: 0.5kg/min (1lb/min).

Compressed air source is necessary. An air

compressor is optional item from manufacturer. As an option, the cutting head

can manually tilt in both x and y directions. |

This equipment is highly recommended for large tables |

|

Requires 70psi

pneumatic source |

| Capacity 40

Gallon. |

| Self detecting

empty/full status of reservoir and start/stop feeding. |

| Model number

ADS-04-170 |

Mini hopper |

|

Mini

hopper is used as a bridge between the automatic abrasive feeder and the

cutting head. The mini hopper also includes a valve to control the flow of the

abrasive. |

Stainless Steel tubing (optional) |

|

The tubing connects the high pressure pump to the cutting head. |

System connection diagram

|